RECYCLING

How it works

The recycling process begins when used PET packaging, in the form of bales weighing 150-500 kg, enters the conveyor system. The bales pass through a crushing mechanism and are then conveyed to the hot pre-wash system. Here, steam-heated water removes most of the sand and other dirt, partially washes off the labels, and removes the caps from the bottles.

-

Step 1

Automatic Sorting Line

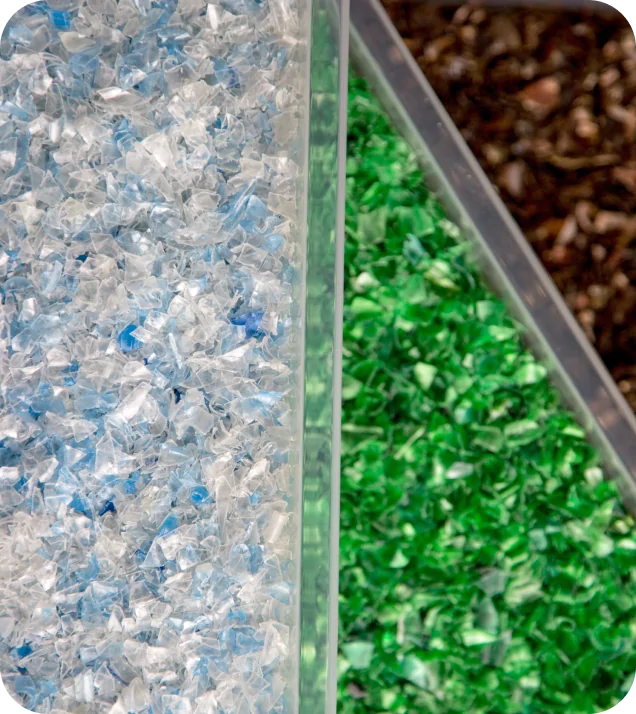

After pre-washing, the PET packaging moves to the automatic sorting line, where it is sorted by color, and other polymers and metallic items are separated from the main PET stream. After automatic sorting, factory workers perform a final visual inspection of the PET flow.

Step 2Second Recycling Line

PET packaging of other colors, after sorting, is directed to the second recycling line, where it is processed into colored PET flakes.

Step 3

Step 3Grinding Mill

The main usable stream after sorting goes to the grinding mill, where it is ground into PET flakes of a specific size.

-

Step 4

Washing Unit

The ground material is transferred to the washing unit using water. Here, under the influence of temperature and an alkaline chemical mixture, glue, attached labels, and other impurities are washed off the PET flakes. Most impurities are separated using a vibrating sieve.

Step 5Flotation Unit

The flakes are then sent to a flotation unit for material separation. Since PET is heavier than water, the PET flakes sink, while the cap and label materials, being lighter, float. These two material streams are separated, and the clean PET flakes go into the rinsing unit.

Step 6Drying and Cleaning

After rinsing, the PET flakes are dried using heated air, and small dust-like particles of PET and adhering paper fibers are removed through a cyclone. At this stage, a metal detector is used to carry out the final cleaning of the PET flakes from metal particles.

-

Step 7

Packaging

The dry flakes are poured into polypropylene bags, sized 100x100x230 cm. The PET flakes are stored in these bags in the warehouse and then delivered to customers.

Step 8

Step 8Resource Utilization

The wastewater generated during production is purified in special wastewater treatment plants. The necessary heat for the process is provided by saturated steam, which is generated by a steam generator. The generator runs on natural gas and electricity. The impurities from the recycling process are sold as raw materials to various polymer recycling companies.